Technologies that actively protect the climate.

-

Our Bag House Filter are highly effective particulate control devices, typically used in heavy industries such as cement, iron and steel, metals, glass, waste-to-energy, fertilizer and biomass. These systems can achieve a particulate removal efficiency exceeding 99.9%, regardless of particle size, thanks to their ability to capture both coarse and fine dust.

Designed for robustness and modularity, they feature pulse-jet cleaning and are equipped for continuous monitoring and remote diagnostics.

We design each baghouse filter based on process parameters, space and specific construction constraints, project logistics and emission requirements. Our filters are tailor-made and customizable in terms of size, shape, bag length, and type of cleaning system used; each choice is done with the focus on ensuring minimal maintenance, long bag life, and optimal filtration performance.

They can be adapted to aggressive dust types, high temperatures, or space constraints, and are compatible with pre-treatment systems (e.g., DSI, PAC). Redecam offers multiple bag materials and cage designs to optimize performance, including smart maintenance solutions for predictive bag replacement.

-

These systems operate on the principle of centrifugal force, which separates particles from the air or gas flow based on inertia differences between solid matter and the carrier gas.

Redecam’s cyclone collectors are used across various sectors including cement, lime, steel, biomass, and waste-to-energy.

Redecam’s Cyclone pre-separators, based on the CFD design, are effective for coarse particle removal and process optimization. These units reduce the dust load upstream of filtration systems, improving overall performance and extending component life. Engineered for high gas volumes and variable particle size distribution, Redecam cyclones are available in multiple geometries and material builds, with integration into multistage filtration setups.

Abrasion-resistant steels or ceramic coatings are employed in highly erosive environments. For high-temperature processes, refractory linings can be included.

Their efficiency, compact footprint, and minimal maintenance make them ideal for harsh industrial environments

-

Redecam’s ESP systems are designed to remove particulate matter from industrial gas streams using high-voltage electrical fields. Our ESPs are engineered for high collection efficiency with minimal pressure drop, offering reliable long-term performance across various process conditions.

Our unique design of the Redecam Rigid Emitting Electrodes ensures their high mechanical resistance (they are manufactured without welding) and their excellent thermal resistance with an optimized geometry to obtain a uniform charging and a strong corona discharge effect. They withstand the highest possible operating voltage while continuing to fully distribute the ionization effect over the entire electrode, meanwhile they achieve stability as it is longitudinally expansion-free.

Redecam’s ESP systems are tailored for different dust resistivity and temperatures, and are installed across multiple industries including cement, glass, metallurgy, biomass and waste to energy production.

Their durability, low operating cost, and high particulate control make them a proven solution in both standard and high demand dedusting environments.

Redecam ESPs are designed for both greenfield and retrofit projects, ensuring smooth integration and optimal layout adaptability due to the tailor-made design studied with CFD simulations.

-

Redecam’s Hot Gas Filters (HGF) are specifically designed for applications requiring gas filtration at elevated temperatures, typically between 250°C and 1000°C. These systems are crucial in industrial processes where traditional fabric filters or ESPs cannot be used due to thermal limitations. Redecam’s HGFs are based on the use of rigid ceramic filter elements, which maintain their structural integrity and filtration efficiency under extreme thermal and chemical conditions

One of the key advantages of Redecam’s HGF systems is their ability to combine the dedusting with catalyst integration for DeNOx and DeVOC purposes. By embedding catalytic coatings on the filter elements or positioning a catalytic layer downstream, the HGF can serve dual functions: particulate removal and NOx reduction. This integrated approach reduces footprint, simplifies plant layout, and minimizes capital and operating costs.

Used in high temperature, this solution ensures ultra-low emissions and efficient heat recovery: a Waste Heat Recovery system downstream installed is therefore smaller, simpler and with optimized performance.

When paired with sorbent injection systems (e.g., sodium bicarbonate or activated carbon), the HGF becomes a comprehensive Air Pollution Control (APC) device for multi-pollutant control.

-

Redecam’s Hybrid Filter merges ESP and bag filter technologies to achieve exceptional dedusting performance, with emissions typically below 5 mg/Nm³ and often down to 1 mg/Nm³. The system combines an electrostatic pre-collection stage with a pulse-jet cleaned fabric filter, ensuring operational stability, lower pressure drops, and extended bag life.

Its architecture merges two key filtration mechanisms: the electrostatic field, which charges and collects dust particles, and the fabric filter stage, which ensures final dust removal and stable emissions regardless of inlet conditions.

The system can be engineered as a retrofit of an existing ESP or as a completely new installation. In retrofit applications, the existing ESP casing is typically reused, minimizing civil work and reducing costs.

Redecam’s Hybrid Filter system features advanced distribution technology, ensuring uniform gas and dust flow across the entire filter area. The internal design is optimized through CFD simulations to avoid dead zones, vortex formation, or channeling effects, maintaining operational consistency and high filtration efficiency over time.

-

Redecam’s Gas Conditioning Tower (GCT) is a high-efficiency solution for gas cooling and conditioning prior to filtration or further flue gas treatment, via controlled water spray cooling.

Equipped with automatic nozzle adjustment and real-time temperature control, it ensures precise dew point approach and uniform gas distribution and also support sorbent reactivity.

Spillback Nozzle System

The spillback system uses high-pressure water forced through a swirl disk to generate a hollow-cone spray pattern. Part of the water is recirculated through a control valve back to the pump, maintaining stable pressure at the nozzle inlet.

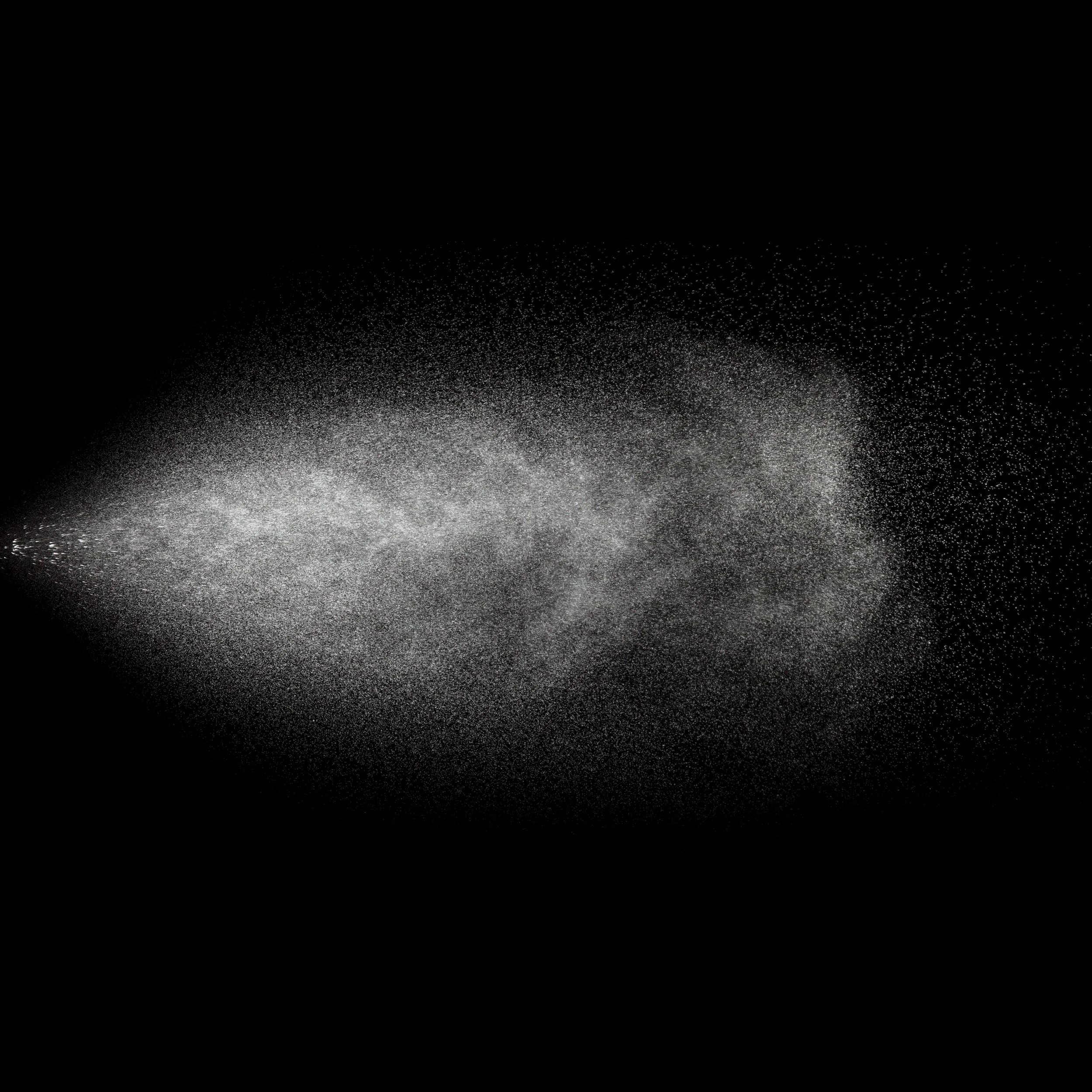

Twin-Fluid Nozzle System

The twin-fluid nozzle system combines water and compressed air for atomization. The media enter separately and mix in the nozzle chamber before exiting through multiple orifices, forming a full-cone spray of extremely fine droplets.

Redecam provides turnkey GCTs with full control system integration, corrosion-resistant materials, and optimized droplet residence time for efficient cooling without saturation risks.

To ensure optimal performance, Redecam employs advanced CFD modelling during the design phase. Simulations performed with ANSYS Fluent allow engineers to visualize gas flow, droplet evaporation, and temperature distribution, optimizing nozzle placement and tower geometry. These simulations also aid in verifying pressure drop and preventing maldistribution.

Typical applications include cement kilns, metallurgical furnaces, waste-to-energy plants, and biomass facilities, where the exhaust gas is too hot for direct filtration.

-

The Redecam’s Water Injection System (WIS) cools flue gases by injecting atomized water directly into the duct. This compact system eliminates the need for a separate cooling tower, making it ideal for retrofits or space-limited applications.

The Redecam’s WIS system consists of a series of specially engineered nozzles installed directly in the gas duct, capable of delivering finely atomized water into the flue gas stream. These nozzles are typically dual-fluid (air and water) or single-fluid (water), depending on process needs and droplet size requirements. The atomized water droplets evaporate upon contact with the hot gas, rapidly absorbing heat and lowering the gas temperature.

Nozzle configuration and droplet control ensure full evaporation within duct length, protecting downstream filters or DeNOx/DeSOx systems. The PLC-based control system adjusts water flow based on real-time temperature readings. Material selection and self-cleaning features ensure durability and low maintenance.

Redecam’s engineering approach for each WIS project includes a thorough analysis of process parameters, CFD simulations, and field experience to ensure the correct design and configuration.

-

Redecam’s Mixing Chambers are designed to homogenize gas flow and temperature profiles before they enter downstream air pollution control equipment.

They are strategically installed in systems where flue gas streams from multiple sources, or with highly variable thermal and chemical characteristics, must be combined into a single, stable stream for optimal performance of downstream air pollution control equipment.

Each Redecam Mixing Chamber is custom designed according to the specific process parameters, including gas flow rate, temperature differential between streams, pressure conditions, and chemical composition. Computational Fluid Dynamics (CFD) modeling is extensively used during the design phase to simulate gas flow patterns, identify recirculation zones, and optimize chamber geometry for complete mixing within the shortest possible duct length.

Flow straighteners or perforated plates are often integrated to optimize distribution.

-

The Redecam Heat Exchanger reduces flue gas temperature to improve filtration and increase energy efficiency, using a crossflow or counter-current configuration depending on the application, with heat exchange surfaces engineered to withstand corrosive and high-temperature environments.

One of the core features of the HEX is its modular design, which allows for easy integration with existing ductwork and flue gas lines. Each unit is fully customized to match process flow rates, temperature drop targets, pressure constraints, and space limitations. The compact layout enables installation in tight industrial environments, making the HEX suitable for both new plants and retrofits.

The heat exchanger’s efficiency is enhanced by flow distribution elements, which ensure optimal gas contact with the heat exchange surfaces. In applications where pressure drop is a concern, Redecam engineers apply CFD simulation to evaluate and minimize flow resistance, balancing performance with energy requirements.

In addition to thermal conditioning, the HEX can be coupled with auxiliary systems such as Bag House Filters or Dry Sorbent Injection Units to create a comprehensive flue gas treatment system.

-

Redecam offers both SNCR and SCR technologies for NOx abatement. SNCR is a cost-effective solution for mid-level NOx reduction, using urea or ammonia injection at controlled high temperatures (850–1050°C) and do not use a catalyst. It relies on direct injection of the reagent into the furnace or a specific point in the process to convert NOx into nitrogen and water vapor. SNCR can achieve lower capital costs and simpler layouts but generally provide lower NOx reduction (30–60%) compared to SCR (80–95%).

SCR systems function by injecting ammonia (NH₃) or urea into the flue gas stream, where it reacts with NOx in the presence of a catalyst to form harmless nitrogen (N₂) and water vapor. These systems typically operate at temperatures between 300°C and 400°C and require a carefully designed catalyst bed, tailored to flue gas composition, particulate levels, and expected ammonia slip.

Redecam supports custom configurations, reagent handling systems, and integration with existing flue gas treatment chains. Our DeNOx units are modular and adaptable for retrofit or new installations.

-

Redecam’s Waste Heat Recovery (WHR) systems are designed to recover residual thermal energy from high-temperature industrial processes and convert it into usable electrical power. This is particularly applicable in cement manufacturing, glass production and steelmaking process.

Based on the Rankine cycle, the main equipment required is the heat exchanger or boiler to be installed on the hot source and a turbogenerator connected to the internal and external electricity grid.

Redecam’s WHR are based on the Organic Rankine Cycle (ORC), using organic fluids like cyclopentane in a closed loop, heated via thermal oil exchangers or on the Steam Rankine Cycle (SRC), realized with steam or high pressurized hot water.

This configuration is ideal for medium-low temperature sources such as cement kilns. Redecam offers modular systems using Clinker Cooler and Pre-Heater boilers, designed to handle dusty, acidic, or abrasive environments. System customization ensures optimal integration with plant layout and energy needs.

Redecam WHR systems are fully customizable based on plant layout, production scale, and grid requirements. Each system is engineered to maximize energy recovery while maintaining the reliability and safety of the process. The company also provides all auxiliary equipment including pumps, piping, instrumentation, and system integration with existing plant operations.

-

Mercury and other heavy metals represent a major concern for regulatory compliance in industrial processes, and they are tightly regulated due to their bioaccumulative and neurotoxic effects.

Redecam’s Mercury Adsorption System (MAS) provides a cost-effective and scalable solution to meet current and future emissions targets. The core principle of the system is the injection of Powdered Activated Carbon (PAC) into the flue gas stream, typically before the particulate control device. The PAC absorbs mercury, furans, dioxins, and other volatile metals, allowing them to be captured in the filter dust.

The MAS can be installed on greenfield plants or retrofitted into existing ductwork. It is frequently combined with other pollutant control technologies such as Dry Sorbent Injection (DSI) or Redecam Dry Scrubber (RDS) for acid removal in hybrid layouts.

Heavy metals such as lead (Pb), cadmium (Cd), arsenic (As), and chromium (Cr) are also captured through adsorption mechanisms.

The system is scalable and adaptable to variable process conditions, supporting real-time modulation and staged dosing. Redecam tailors PAC type and injection strategy based on gas temperature, mercury speciation, and dust load.

-

Efficient Multi-Pollutant Control with Compact, Sustainable Design

Built on decades of experience in air pollution control, RDS combines performance, reliability, and sustainability in one intelligent system.

Redecam’s Circulating Dry Scrubber (RDS) provides high‑efficiency, multi‑pollutant control for SO₂, SO₃, HCl, HF, Hg, and other acid gases, combining low water use, low maintenance, and zero wastewater.

Its semi‑dry, corrosion‑free process and robust construction ensure long‑term reliability under varying operating conditions.The circulating fluidized bed reactor enhances performance by continuously recirculating solids, maximizing sorbent utilization and reducing waste. Uniform gas distribution and a compact reactor design deliver high throughput with minimal footprint. Smart process controls automate reagent injection, monitor SO₂ and Hg emissions in real time, and stabilize temperature, pressure, and recirculation to ensure consistent compliance.

RDS offers up to 40% lower energy consumption compared to wet scrubbers, thanks to low pressure drops and the absence of pumps or wastewater treatment. Optimized stoichiometry (Ca/S = 1.3–1.5) and high recycling rates further reduce reagent usage and operating costs.

With removal efficiencies up to 99% for SO₃, HCl, HF, Hg, and other acid gases, modular construction, and broad industrial applicability, RDS delivers a reliable, cost‑effective, and sustainable air‑pollution control solution.

-

The Redecam’s Dry Sorbent Injection (DSI) is a flexible and efficient solution for the control of acidic pollutants such as sulfur oxides (SOx), hydrochloric acid (HCl), hydrofluoric acid (HF), and heavy metals including mercury (Hg) in flue gases. The process involves injecting a sorbent—typically hydrated lime (Ca(OH)₂), sodium bicarbonate (NaHCO₃), or activated carbon (PAC)—into the gas stream upstream of the particulate control device.

For applications requiring maximum removal efficiency, Redecam offers an optional Dry Reaction Tower (DRT) upstream of the particulate control device. This tower increases the residence time between the reagent and the gas stream, allowing for more complete acid-gas neutralization and enhanced sorbent utilization efficiency.

DSI systems can be implemented as retrofit solutions due to their relatively compact footprint and minimal infrastructure requirements.

The dry approach avoids wastewater treatment and minimizes CAPEX/OPEX compared to wet scrubbing. Our DSI systems are scalable and equipped with dosing optimization, injection grid design, and integrated emission monitoring. Ideal for industries requiring flexible, low-maintenance emission control with fast deployment.

From technology provider

to full turn-key partner.

• In the realization of the complete flue gas treatment projects, Redecam operates either as general contractor (turn-key solutions) or as technology provider, either to engineering companies or to end-users.

• Redecam has a long history of partnerships with various international engineering companies and is acting as a key technology provider

• A typical Redecam project mainly involves all the departments of the company; it encompasses: the sales & proposal engineers, the technical team, and the supply chain department, coordinated by the project management. After sales completes the value chain.