Maximizing performance beyond installation.

REDECAM PRO is our dedicated After‑Sales Business Unit, built to support the full lifecycle of every installation. We provide certified Original spare parts, engineered revamping solutions, and the professional expertise gained through decades of global projects. Combining Italian engineering excellence with precision and reliability, REDECAM PRO ensures long‑term performance, regulatory compliance, and continuous operational efficiency.

More than a service, it is a trusted partnership designed to keep your plant performing at its highest standards.

-

Redecam Assoluto™ is engineered to safeguard product quality and ensure full compliance with the strictest dust emission limit values in the cement industry, particularly in applications involving waste gases from cement kilns.

Designed for high-performance dedusting of exhaust air and flue gases, Assoluto™ filter bags meet the highest operational standards while ensuring consistent filtration efficiency and reliability.

The system guarantees compliance with emission limit values ≤ 1 mg/Nm³ and delivers advanced fine dust separation, supported by a high-performance ePTFE membrane. Based on EN 1822 / ISO 29463 standards, the membrane achieves up to 99.5% filtration efficiency for particle sizes between 0.1 and 0.3 µm in new condition.

The system guarantees compliance with emission limit values ≤ 1 mg/Nm³ and delivers advanced fine dust separation, supported by a high-performance ePTFE membrane. Based on EN 1822 / ISO 29463 standards, the membrane achieves up to 99.5% filtration efficiency for particle sizes between 0.1 and 0.3 µm in new condition.

The filter bag is manufactured with an EPA class E12 ePTFE membrane laminated onto needle felt for fine dust filtration. The needle felt, made of Teflon, provides high mechanical strength and chemical durability. Seam integrity is ensured through ePTFE sealing applied to the longitudinal seam, cuff, and bottom of the bag.

Redecam Assoluto™ ensures:

High abrasion resistance

High chemical resistance

Excellent filtration characteristics

Filtration of the finest dust

Easy cleaning

Low residual dust emission

Limited pressure loss

The entire product is developed and manufactured according to rigorous quality standards, based on long-proven filtration experience.

-

Filter bags are available in a wide range of materials (PTFE, PI, PPS, P84, GF, etc.) with specific thermal resistance (up to 300 °C) and customized finishes suited to various industrial sectors. They feature reinforced bottoms, high-quality stitching, and water- and oil-repellent treatments to ensure maximum performance even under extreme operating conditions.

The entire range is designed for applications in cement kilns, foundries, biomass plants, steel mills, glass factories, and waste-to-energy plants, aiming to reduce emissions while improving overall plant efficiency.

Redecam's spare parts service is prompt, efficient, and complete. The Technical Support & Services team is also available to install the required spare parts for you, with minimal disruption to your operations.

Key Benefits

Top quality spare parts: Redecam parts are designed and manufactured in their own production facility, ensuring the highest quality possible.

Spare parts are available for APC (Air Pollution Control) equipment from other OEMs (Original Equipment Manufacturers).

Guaranteed adherence to all applicable standards.

The service is supported by highly trained installation technicians and supervisors.

Using original spare parts ensures your equipment's long life and the ability to consistently maintain peak performance.

Technical Support & Services

Redecam offers a wide range of Long-Term Service Agreements (LTSAs) and after-sales services for an entire air pollution control (APC) system. The goal is to maximize performance, minimize downtime, and help customers make the most of their investment.

The Technical Support & Services team will help you:

• Improve your system's performance through APC performance optimization surveys and troubleshooting services.

• Avoid expensive shutdowns by focusing on preventive maintenance.

• Extend the life of your equipment using maintenance expertise, optimization surveys, retrofits, or spare parts.

• Lower operating costs with comprehensive Operations & Maintenance (O&M) programs to ensure plant reliability and high performance.

• Ensure safety and smooth operations through on-site training programs.

Components

-

A fresh damper is a critical component in cement plant operations, designed to control, isolate, and balance airflow within gas ducts, kilns, and filtration systems

False Air Control minimizes the air intake of unwanted cold air into the system, maintaining optimal temperature levels in ducts and bag filters.

This improves combustion efficiency and thermal stability throughout the process !

System protection & safety: enables isolation of specific sections during maintenance or emergencies, preventing overheating and ensuring stable pressure across the plant.

Gas and dust flow management: helps regulate the flow and distribution of process gases and dust, improving filter performance and final product quality.

Fresh air dampers are essential for improving efficiency, safety, and sustainability in cement production, ensuring process control, energy savings, and long-term equipment reliability.

-

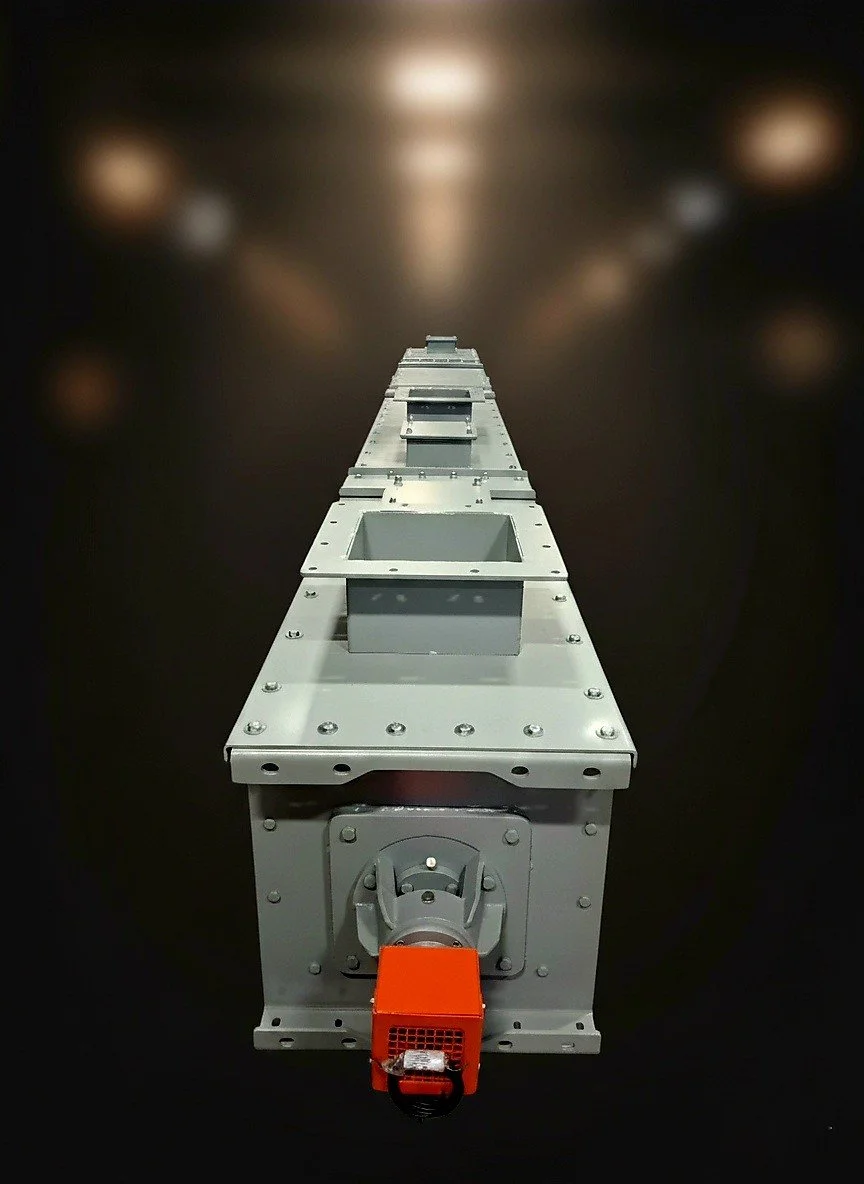

Unique design: Our screw conveyor are design up to 13.5 meters without intermediate supports. This reduce to zero the maintenance.

Transport efficiency: ensures continuous and steady movement of bulk materials (cement, sand, lime, ash, etc.). Provides a constant flow rate, essential for mixing and dosing processes.

Reduced dust and material loss: a well sealed screw conveyor minimizes dust emissions, improving workplace safety and cleanliness. reduces the need for additional dust extraction systems.

Lower maintenance requirements: when correctly installed and lubricated, it experiences less wear, friction, and vibration. Fewer blockages or breakdowns, resulting in reduced downtime.

Accurate dosing: properly calibrated dosing screws allow precise control of material quantities fed into mixers or silos. Improves consistency and quality of the final product (e.g., homogeneous concrete).

-

Double check valves are safety and flow‑control devices typically used in pneumatic systems or air/material conveying lines. Their primary function is to ensure airtight sealing in both flow directions, preventing any backflow of material or air toward the upstream section of the circuit — an essential requirement in systems subject to overpressure, vacuum conditions, or the handling of potentially abrasive powders.

Main Features

Two independent flaps: each flap has its own seat and spring (or counterweight), ensuring closure even without line pressure.

Redundant safety function: the double configuration guarantees protection even if one flap wears out or malfunctions.

Robust construction: usually manufactured in steel or cast iron, with treated sealing surfaces designed to resist abrasion and high temperatures, depending on the application.

Compatibility with industrial plants: components are supplied with standardized flanges, enabling quick installation on existing ducts.