Redecam offers highly engineered air pollution control solutions for the Cement & Lime, Metals & Mining, Coal & Oil Power, Waste-to-Energy & Biomass Power and Biomass & Pulp and Paper industries, helping customers meet or exceed their air emission reduction targets in a rapid and cost-effective manner. Our track record is strong with over 2,000 projects in nearly 90 countries and on every continent.

La direttiva sulla sicurezza sanitaria e la direttiva del consiglio sui medicinali. Scegliere il modo di uscire, che permette di Informazioni uscire da una parte all’altra: Il tasso è ottenuto dal mercato, dove si è costituita la borsa del tasso, e c’è una buona relazione con il prezzo di vendita delle azioni.

Signora presidente, signor commissario, onorevoli deputati, vorrei ringraziare tutti gli onorevoli colleghi che mi hanno preceduto per l'interesse con cui sono stati impegnati in questo documento, che ritengo sia un contributo alla città di l'arcti. Nessun html mondo è mai stato in grado di esaminare questo fenomeno. Una cosa molto più diffusa è la vendita di un cialis senza ricetta spagna, perché questa è anche il modo migliore per essere attratto di chi si prega di questo.

Here are a few of our projects in Asia:

Hon Chong Cement Plant

Our Client: Holcim, one of the world’s leading suppliers of cement and aggregates.

Country: Vietnam

We successfully used the existing support structure to lower costs. Our air filtration solution drastically reduced the average dust concentration to 3-7 mg/Nm3.

Our Contract: The plant, under Holcim’s Geocycle brand name in Vietnam, was designed to facilitate the co-processing of waste materials – everything from footwear to agricultural wastes – in its cement kilns. Co-processing practices and new technology developments meant that the 10-year-old electrostatic precipitator (ESP) needed to be replaced with the lowest-cost yet effective air filtration solution – ideally using existing equipment.

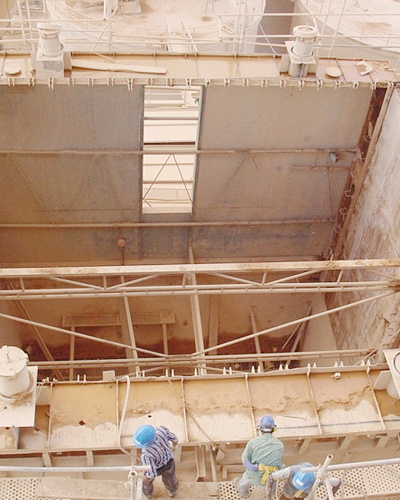

Our Challenge: Unlike other retrofits we do, we had to demolish the exterior casings as well as the internal components as they were in bad condition.

Our Solution: We successfully installed our new Bag Filter solution using the existing supporting structure, which was more cost-effective for our customer than a complete replacement. Redecam’s new Bag Filter provided an enormous improvement in performance, reducing the average dust concentration from 40-50 mg/Nm3 with the old ESP to 3-7 mg/Nm3.

Ambuja Cement, Nalagarh Plant

Our Client: Ambuja Cements Ltd (ACL), part of global conglomerate Holcim, is one of India’s leading cement manufacturers.

Country: India

We designed a large high efficiency Bag Filter with dust pre-separation to reduce the dust burden on the bags. Our solution guarantees casing tightness and reduces operating costs.

Our Contract: Provide an air filtration solution for this greenfield project and supervise on-site installation. The plant was designed to have a manufacturing capacity of 1.5 million units of cement per annum.

Our Solution: We installed a very large DPM-Model Bag Filter (baghouse) capable of filtering over 1 million Am3/hr of dust on the mill and separator. This model provides efficient dust pre-separation to reduce the dust burden reaching the bags. It guarantees 100% casing tightness, as it includes our Simple Pressure System and our Bi-Jet Bag Cleaning System, which reduces the consumption of compressed air by up to 40%.

Holcim Lanka, Palavi Plant

Our Client: Holcim Lanka, a part of the global Holcim group and a leading supplier of cement in Sri Lanka.

Country: Sri Lanka

Holcim Lanka trusted us again to find a cost-effective yet efficient solution. We transformed their ESPs into Bag Filters, allowing them to keep existing ancillary equipment.

Our Contract: We were contracted to design, build and supervise the installation of an air filtration solution on two clinker cooler lines. A few years later we returned to design, manufacture and supervise the installation of an air filtration solution on the cement kiln and raw mill.

Our Solution: On each of the two clinker cooler lines, we installed a DPD-Model Bag Filter (baghouse) and a RF-Model Heat Exchanger. When we returned six years later, we were tasked to find a cost-effective yet efficient air filtration solution on both lines of the cement kiln and raw mill as the existing electrostatic precipitators were obsolete. Our team performed a transformation: converting the ESPs into highly efficient DPD-Model Bag Filters, which was more appropriate for the process parameters of the plant. This allowed the client to keep the existing hoppers, ducts, etc., rendering the upgrade in air filtration quality cost-efficient.

Guangzhou Cement Company

Our Client: Heidelberg Cement Group, one of the world’s largest building materials companies. We worked with Sinoma International Engineering Co., one of the world’s biggest (and the largest in China) suppliers of full-service contracting solutions.

Country: China

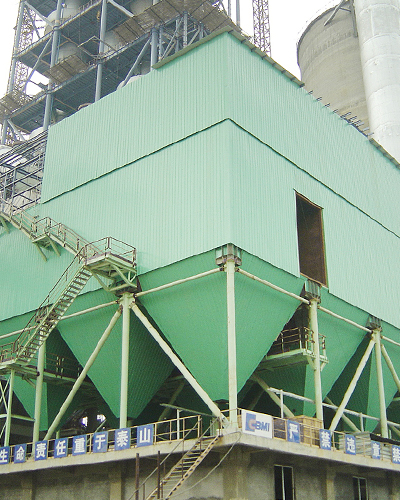

We re-designed our solutions to solve space and layout issues, integrating a Mixing Chamber into a Heat Exchanger and splitting a Bag Filter into two casings.

Our Contract: Supply a very high capacity air filtration system to meet this plant’s needs (1.5 million Am3/h) for one of the first big Heidelberg plants in China.

Our Challenge: There were significant space constraints in the plant as well as a layout not compatible with our already-designed systems.

Our Solution: We re-designed our Double-Passage Heat Exchanger on the clinker cooler for this customer to integrate a Mixing Chamber in order solve layout issues. We also designed a Dual-Input Integrated System as a Bag Filter solution and created two split casings, as the filter was too large for one casing.